Electrical Enclosures

Electrical Enclosures are enclosures in which electrical distributions and connections or controls are installed. The controls may be electrical, electronic, pneumatic, hydraulic or optoelectronic or a combination thereof.

A control system is comparable to a computer, but with very specific tasks. Essentially, a control system consists of the inputs, the control unit and the outputs. The inputs include, for example, cables that supply the control unit with the measured values from sensors or that come from buttons, knobs or a touch panel for operating the control unit. Electrical controls are often programmable logic controllers (PLCs). Depending on the application, certain programmes are stored in this, which lead to defined reactions at the outputs when certain information is present at the inputs. The outputs are used to forward information to displays, to actuators, to control motors and much more. For this reason, control cabinets are usually required for all machines and systems, especially in the production area. Sometimes the control cabinets are not recognisable as such because they are located behind a casing or panel.

Switch cabinets to make assembly easier

The reasons for using a control cabinet are, on the one hand, that the control or distribution system is to be protected from external influences and, on the other hand, that a control cabinet simplifies the construction of a control system. These two points are also the main distinguishing features of a control cabinet from a sheet metal enclosure.

Control cabinets facilitate the control assembly because they contain a variety of mounting options for the control components, whether through perforated profiles, support and latching rails, direct mounting on the mounting plate or individual mounting options. This also allows the power and control sections to be separated from each other. Switch cabinets are usually equipped with one or more removable flange plates that allow cables to be fed in - even at a later date - sealed with the aid of PG glands. Switch cabinets are available in standard sizes, but any size can be realised if required. Control cabinets already contain the bare bolts that ensure proper earthing of the control cabinet housing to the screw-off control cabinet parts such as the door and mounting plate. Control cabinets have one or more doors or covers. This means that the control system is always accessible for assembly, maintenance and repairs. Great flexibility is provided when the enclosure door can be changed from left to right-hand stop without great effort.

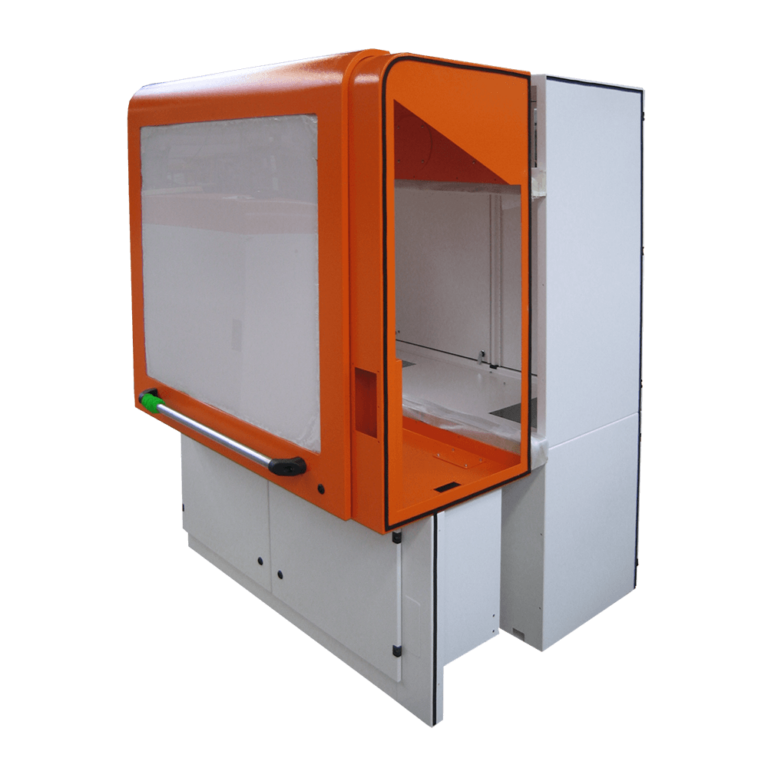

The standard colour for control cabinet enclosures is RAL 7035 (light grey), although any other colour is possible, e.g. the customer's or machine manufacturer's corporate colour.

Protection for control or distribution

Control cabinets protect the control or distribution system. Electrical and electronic components in particular require effective sealing against external influences. For example, the penetration of liquids such as water or oils must be prevented. Dust, sand, dirt and other solids would also be detrimental to the function of the interior of control cabinets. Because control cabinets are usually very tight, it is also possible to keep too high or too low temperatures away from the control system or to dissipate them. In the simpler case, this is achieved in conjunction with fans, otherwise with attached air-conditioning units and heaters.

Sealing is achieved by various measures. For example, the enclosure door is always fitted with a seal towards the enclosure housing, ideally with a captive foamed-on seal without a joint. This also applies to the flange plates. The enclosure housing frame is edged several times (rain gutter) so that, in addition to sealing, there is additional protection against the ingress of water and dirt. As a consequence, this means that media-tight enclosures allow the installation of components that are themselves hardly protected. Switch cabinets where there is a risk of touching internally live components can only be opened with tools (double-bit, square or cylinder keys).

Metal control cabinets also help to shield against electromagnetic radiation.

Protection class for control cabinets

One way of assessing tightness is the IP standard. The degree of protection of enclosures of electrical equipment against the ingress of solid objects and water, as well as the protection of the operator against contact with dangerous parts, is specified in the IP codes. Hazardous parts are all components in an enclosure that can cause an electric shock by approaching and/or touching them and moving parts that can pose a mechanical hazard. The classification of enclosures is regulated in DIN EN 60529 or IEC 529. IP codes are to be specified according to the scheme "IPXX". IP stands for International Protection. XX are the placeholders for two code numbers. The first code number stands for protection against the ingress of solid bodies as well as for the protection of the operator. The second digit indicates the degree of protection against water. The higher the respective digit, the higher the degree of protection.

Do you have a need for control cabinets?

Lippert, your competent manufacturer for control cabinets in series and special design.

The Lippert company has been manufacturing control cabinets for more than 50 years. More than 50,000 control cabinets per year are the basis of the comprehensive wealth of experience.

Standard enclosures in the product range are:

Next to it special electrical enclosures produced according to customer requirements in any type, shape, size, functionality and colour.

- Anton Lippert GmbH

- Einsteinstraße 1

- 89407 Dillingen/Danube

- Tel. 09071/7939-0