electrical enclosures

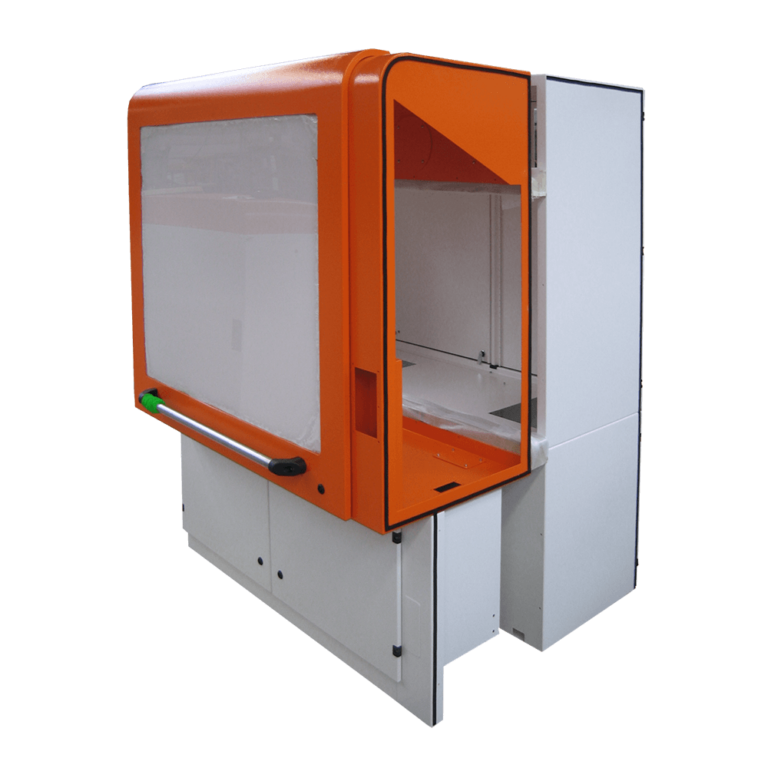

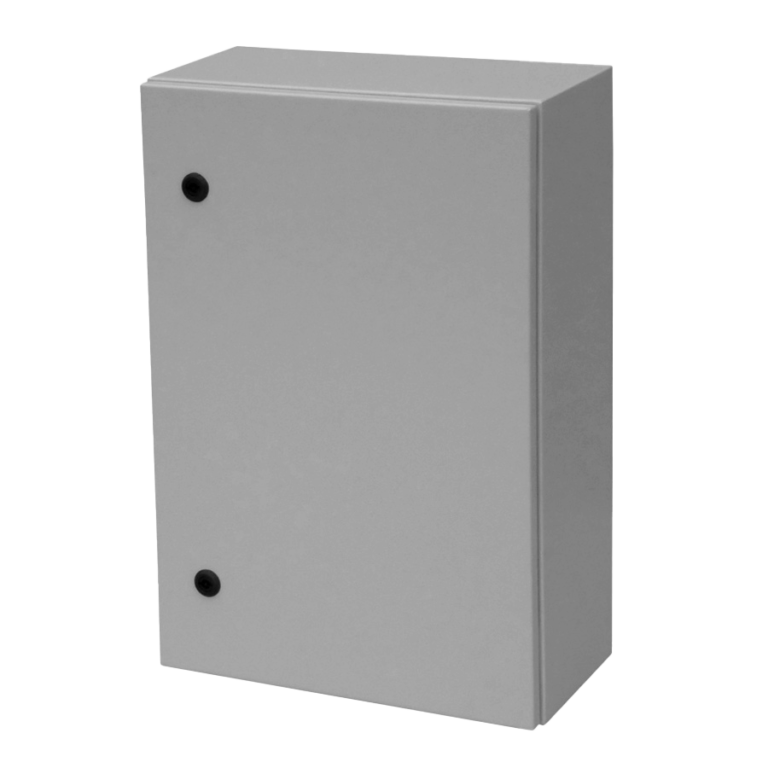

A small electrical enclosures is called a terminal box. The name is derived from the possibility of connecting various electrical cables in terminals in a protected and organised manner. The middle size of an enclosure is called a wall-mounted enclosure. Wall-mounted enclosures are attached to walls or directly to machines or systems. The floor-mounted counterpart to wall-mounted enclosures are (control) consoles. Control panels usually have two operating surfaces, one almost vertical and one largely horizontal. The upper part houses display elements such as displays. Control centres for large systems and power plants are usually designed in console form.

The spacious enclosure for large control units and distribution boards is a floor-standing or bayed enclosure. This size of enclosure requires an additional enclosure frame on the inside for stability reasons. Compared to a floor-standing enclosure, a bayed enclosure extends the range of applications because it can be easily linked with other bayed enclosures to form a large unit. This means that the enclosure can be modularly adapted to the required space. This is achieved by omitting the side panels between the individual joints. This means that the cables, lines and power conductors can also be laid continuously.

Application and accessories

Depending on the application, the accessories for an enclosure are also important. Examples of this are the complete air conditioning technology, i.e. filter fans, air conditioning units and heaters. There are different types of locks, e.g. square, double-bit, toggle or swivelling lever locks or with padlock. There are various flange or cable plates, which are important for cable entry. The earthing or protective conductor connection between the removable parts of the enclosure must not be forgotten. A rain cover should be considered for an outdoor enclosure. Floor-standing and bayed enclosures often stand on a plinth. A circuit diagram pocket is recommended for later storage of documentation on the inner workings of an enclosure. A light in the enclosure is an advantage in poorly lit environments. Transport lugs are important when handling a heavy enclosure. Apparatus rails/hook rails enable control components to be attached.

A swivelling frame can be used to extend the mounting area. This makes it possible to mount additional components in the switch cabinet.

Materials

An enclosure is made of steel, aluminium, stainless steel or plastic. Each material has advantages and disadvantages. Therefore, the choice of material depends on the application. If the focus is on a favourable price and stability, sheet steel will be the material of choice. In paint-damaging atmospheres and in the food industry for hygienic reasons, an enclosure made of stainless steel is often used.

Types of protection

An important criterion for an enclosure is the degree of protection. It expresses how well an enclosure protects the inner workings against external influences. The degree of protection is standardised in DIN EN 60529 and is indicated by "IP" followed directly by two code numbers, e.g. IP66. The first code number expresses the protection against foreign bodies and contact.

1 is protected against solid foreign bodies with a diameter of 50 mm and larger. This means that a ball with a diameter of 50 mm must not penetrate fully into the switch cabinet.

2 means protection against solid foreign objects with a diameter of 12.5 mm and larger.

3 is protected against solid foreign bodies with a diameter of 2.5 mm and larger. Protection class 4 covers foreign bodies with a diameter of 1.0 mm.

5 stands for dust-protected, which means that the ingress of dust is not completely prevented. However, dust must not penetrate to such an extent that the safety or operation of the appliance is impaired.

6 is the code number for dust-tight. No dust may enter the switch cabinet at a negative pressure of 20 mbar.

The second code number of the protection class refers to the protection against water ingress into the switch cabinet. With 1, the switch cabinet is protected against dripping water. Vertically falling drops must not have any harmful effects. 2 complicates the above conditions by an inclination of the enclosure of up to 15 degrees on either side of the vertical. If the value of the second code number is 3, this means protection against water spray. Spray water is water that is sprayed at an angle of up to 60 degrees on either side of the vertical. At 4, the enclosure is protected against splash water, meaning that there are no harmful effects from water splashing against the enclosure from any direction. A value of 5 stands for water jets, which are also directed against the enclosure from any direction. 6 intensifies the protection against strong jets of water, otherwise as with 5. The degree of protection 7 expresses the protection against the effect of temporary immersion of the enclosure in water. Water must not enter the enclosure in a quantity that causes harmful effects if the enclosure is temporarily immersed in water under standardised time and pressure conditions. 8 is the protection for permanent immersion in water. This involves the enclosure being permanently submerged in water under conditions that must be agreed between the contracting parties. However, these must be more difficult than the conditions of protection class 7.

There is another degree of protection, 9K, but this is regulated in DIN 40050, Part 9. Exposure is with water from a high-pressure or steam jet cleaner. This water from any direction must not have any negative effects.

An electrical control cabinet with a control unit usually has an externally accessible emergency stop button or a suitable main switch. This allows the system or machine to be stopped or de-energised in an emergency. A shut-off option for this switch-off device prevents it from being switched on during maintenance and repair work.

Are you looking for an outstanding enclosure manufacturer?

The company Lippert is a competent supplier of standard and customised control cabinets.

Over 50 years of manufacturing enclosures have led to a wealth of experience. With more than 50,000 enclosures per year, Lippert proves its outstanding level of quality time and time again.

Standard enclosures in the product range are:

Next to it special electrical enclosures produced according to customer requirements in any type, functionality, colour, shape and size.

- Anton Lippert GmbH

- Einsteinstraße 1

- 89407 Dillingen/Danube

- Tel. 09071/7939-0